As a two-wheeler producer, turn your customers into eternal fans.

Secure a competitive edge with Traction‑X’s patented ride comfort and safety advantage.

The design of a scooter with Traction‑X powertrain suspension

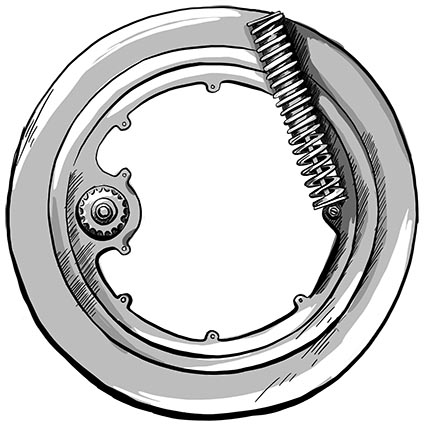

Using the example of the electric scooter illustrated in Figure, the potential of the new drive concept has been illustrated in an artistic representation.

A conventional scooter has a so-called power train swing arm, which contains motor and secondary drive within a rotating level. The serious disadvantages of this design have been described in the section state of the art. Alternatively, the motor is arranged in the center of the chassis or frame, and the power transmission to the rear wheel in done via a belt or chain drive. The rear wheel is mounted in the chassis by means of the swing arm. Neither the use of the installation space nor the function are nearly optimal.

An electric scooter equipped with Traction‑X would allow the motor to be rigidly mounted to the frame and within the rear wheel (see illustration). The significantly enlarged rear wheel is also the rocker arm for shock absorption and damping. The space gained facilitates to accommodate part of the battery below the seat and in front of the rear wheel, so that the footwell is completely available to the driver. Driving stability, rolling comfort and agility of the vehicle are significantly improved, as described in section the innovation.

The overall vehicle and its outstanding technical improvements will represent nothing less than a technical revolution!

Traction - X

is a new and patented system of transmission and suspension for scooters, which is particularly light and compact allowing an increase of the wheel diameter, thus yielding beneficial effects on the driving characteristics.

THE DRIVE

A combination of secondary drive, drive wheel and wheel suspension

As a passionate motorcyclist, I am not averse to the comfort of a scooter, but I do not want to accept the significantly poorer riding characteristics and the deficit in safety compared toa motorbike. As an engineer, I have therefore developed a new system that combined power transmission and wheel suspension and thus merges the advantages of the motorcycle with the advantages of the scooter. That is Traction‑X!

I have been a passionate motorcyclist for most of my life. In addition to enjoying the riding experience, feeling close to nature and a feeling of freedom, my enthusiasm is also based on a inquisitiveness for the innermost technical connections of motorcycles, these marvels of mechanics, electrics and electronics. Part of my passion has always been the pleasure of doing manual work when I dismantled my motorcycles to restore or maintain them and at the same time reveal their technical secrets. In later years, when I asked for more comfort, I found that many of the features of modern scooters suited me, but that I was forced to accept some significantly poorer riding characteristics compared to the motorcycle. As a technically ambitious engineer, I soon began to think of a remedy.

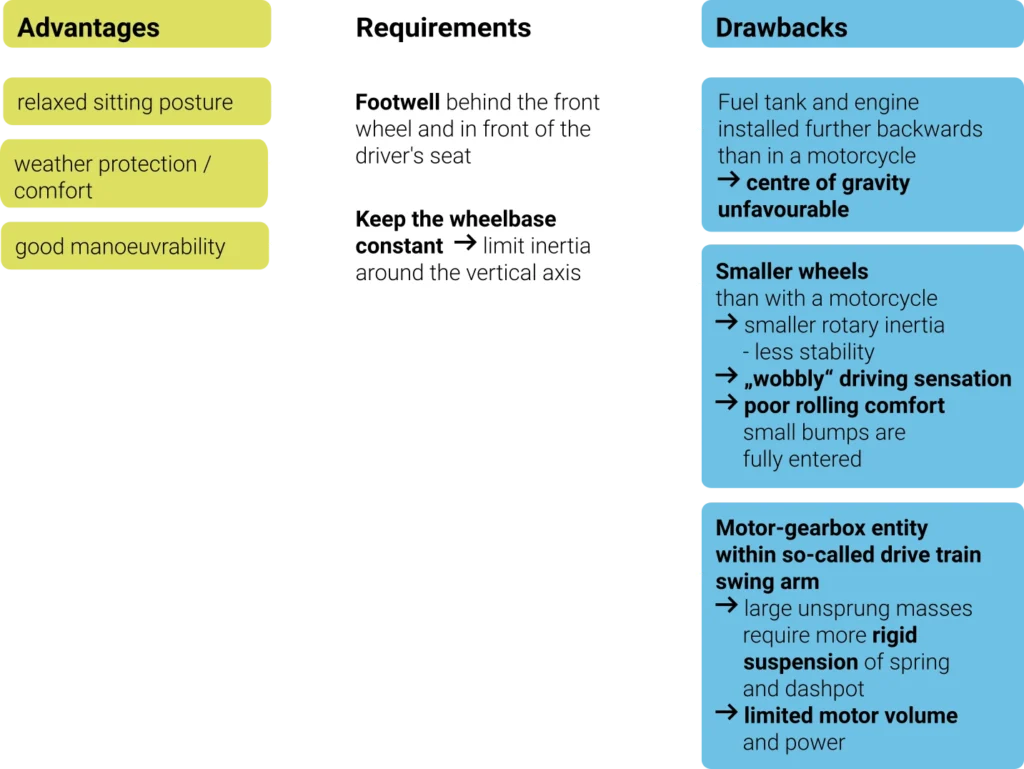

The following is a brief analysis of the requirements, circumstances and derived properties of the competing two-wheeled concepts: A motor scooter is characterized in that there should be a splash-proof footwell behind the front wheel and in front of the driver’s seat, allowing the rider a natural and relaxed sitting posture. A motorcycle, on the other hand, is characterized by the fact that the fuel tank and an engine are located between the legs of the seated rider. Both assemblies must therefore be positioned further back in a scooter. This would theoretically increase the scooter wheelbase. However, since the wheelbase of a two-wheeler must not become too large, all scooters designed so far were forced to limit it by a combation of essentially two measures. The first measure to reduce the wheelbase is to installation of smaller wheels compared to the motorcycle. However, this has three negative effects

- The driving stability of the scooter is lower compared to a motorcycle, because the stabilizing angular momentum of the smaller wheels is lower, and consequently the driving behavior of scooters is often perceived as “wobbly” and “nervous”.

- The rolling comfort of the smaller wheels is significantly worse, since due to their smaller diameter, even small potholes or unevennesses on the road are fully traversed.

- Driving safety is lower because the smaller contact area or the smaller “tyre swath” means that there is less grip on the road.

The second popular measure to limit the wheelbase of any scooter is the installation of so-called drive train swingarms, which combine the motor-gearbox assembly with auxiliary components including secondary drive as a large suspension lever. The negative effect of this technical measure is the large unsprung mass, which must be counteracted by a hard spring coefficient and greater damping of the rear wheel suspension. As a result, the overall suspension ride comfort is comparatively poor.

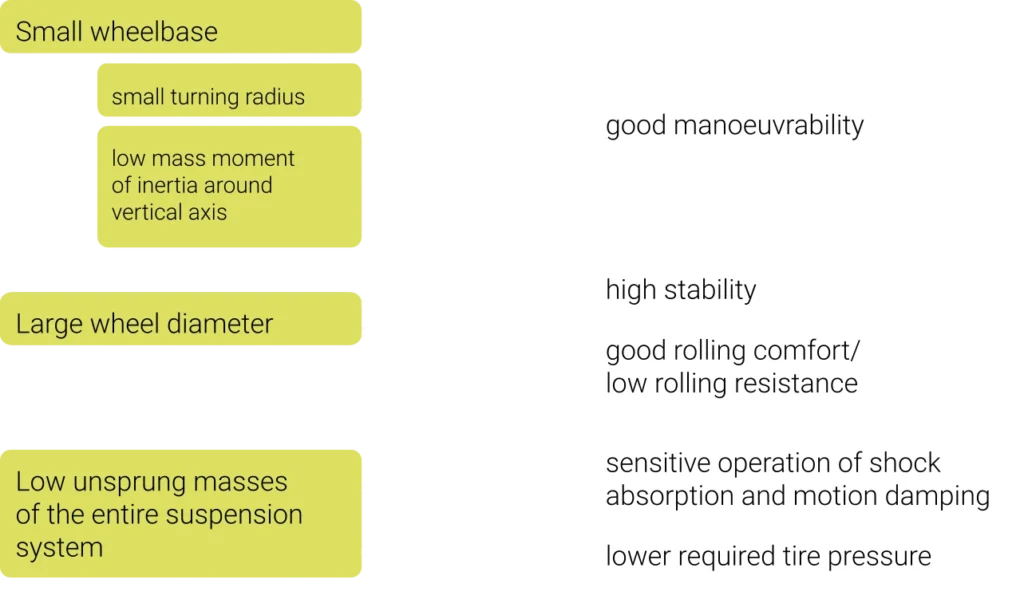

The customer wishes and requirements for a relaxed seating position, weather protection, comfort and a maneuverable vehicle, as shown in the figure are therefore bought with several disadvantages with conventional motor scooters.

This is exactly where the Traction‑X invention comes in, combining all the advantages of the scooter with all the advantages of the motorcycle, “the best of both worlds”, so to speak..

PROOF OF CONCEPT

The Demonstrator

In cooperation with the Institute of Automotive Engineering at the Cologne University of Applied Sciences, a scaled demonstrator of Traction‑X has been created. This 3D-printed model, animated by means of a micro-PC, is proof of the feasibility i.e., of the Traction‑X concept.

Details can be read at the blogpost Demonstrator.

Traction - X

@ Labor‑X Hamburg

Traction‑X zu Gast bei Dr. Jan Evers

Last month, Traction‑X was a guest of start-up consultant Dr Jan Evers in Hamburg’s LaborX. His podcast “Ideencouch” is a very special appreciation for all start-ups and budding entrepreneurs. We received a treasure trove of tips and good expert advice in the conversation. In addition, we had a lot of fun!

Many thanks to Jan and his team at the LaborX!

STATE OF THE ART

What is the technical status quo of two-wheeler technology?

Conventional motorcycles often have a secondary drive by means of a link chain or toothed belt. The state-of-the-art in drive technology for these motorcycles is the functional and spatial separation of the drive shaft and swing arm axis, in combination with the central mounting of a conventional rear wheel. The disadvantage of this design is the variability of the distance between the chain sprocket and the rear wheel sprocket in the chain drive or between the front and rear pulley in the belt drive. The deflection of the rear wheel when driving over a bump leads to noticeable repercussions in the drive train, i.e. on engine speed and torque.

The state of the art in scooter drive trains is the combination of a so-called swing arm drive train with a conventional rear wheel that has a central mounting. A swing arm drive train is an integral design of engine, transmission and rear wheel swing arm. The motor and drive housing is swivel-mounted in the motorcycle frame and follows the movements during the compression and rebound. The drive shaft and swing arm are also functionally and spatially separated. The disadvantage of this design is the large unsprung mass, i.e. the large moment of inertia, which results in a moderate response and comfort of the rear wheel suspension. The advantage of this design is the constant distance between the chain sprocket and the rear wheel sprocket in the chain drive or between the front and rear pulley in the belt drive.

THE PATENT

Click here to access files at the German Patent and Trademark Office

The invention on which Traction‑X is based is a device for transmitting the drive torque from the engine of a wheeled vehicle to its drive wheel and for shock-absorbing and resilient suspension of the drive wheel itself. An extremely compact design is achieved, which features great advantages especially for motor scooters.

The invention of the Traction‑X was motivated by the task to develop a compact unit for power-transmission and wheel suspension for a motor scooter, which meets the following requirements

- A short wheelbase of the two-wheeler in combination with a small turning circle and a low moment of inertia around its vertical axis were sought to realize, with the aim to achieve good agility and mobility of the scooter.

- A large wheel diameter was sought to facilitate, so that driving stability, road-holding, and ride comfort are significantly improved compared to conventional scooters.

- The mass of the motor-gear unit should have no influence on the shock-absorbing and spring-loaded wheel suspension, i.e. the unsprung mass of the entire wheel suspension should be small, regardless of how large the motor-transmission unit is.

Technically, the Traction‑X invention could be referred to as a “drive arm wheel suspension”. It combines the functionality of three technical components

- the secondary drive from the motor or transmission output to the drive wheel, depending on whether it is an internal combustion engine or an electric motor drive

- the swing arm or the rocker arm of the resilient suspension, and

- the drive wheel itself.

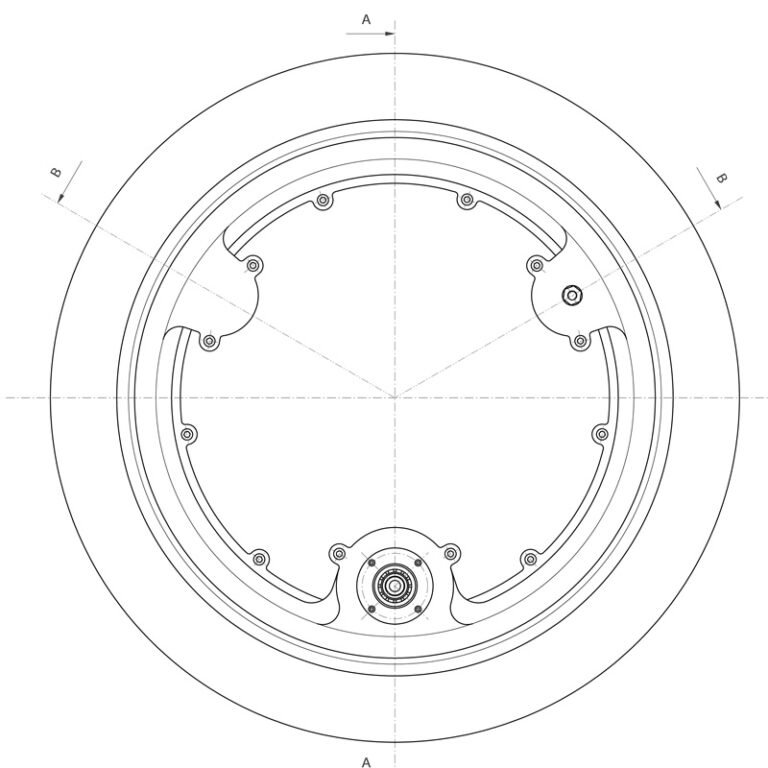

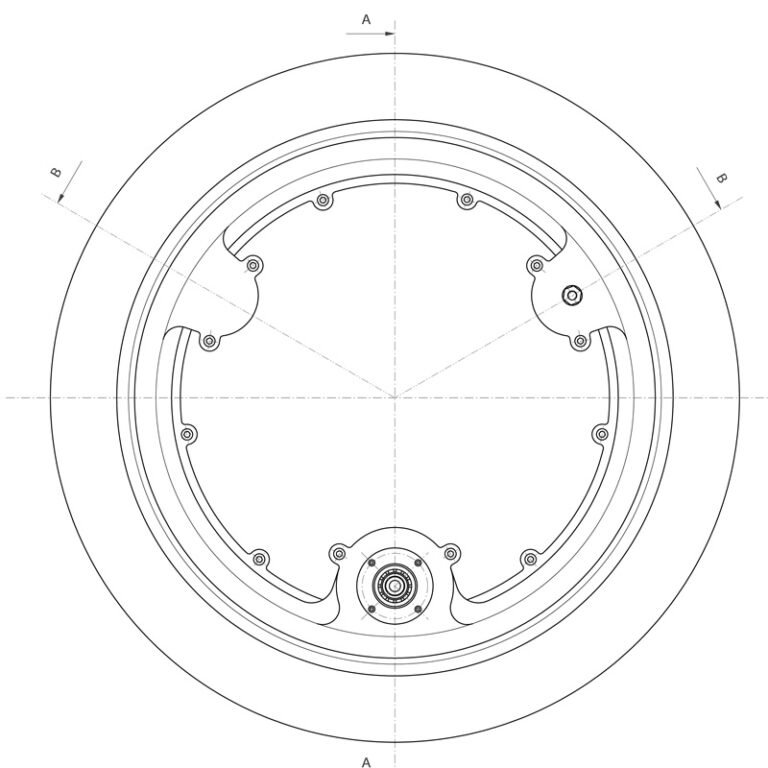

For this purpose, Traction‑X features a very large wheel bearing, which has the same dimensions as the wheel rim itself, so that there is an inner ring inside the wheel, which is not rotating w.r.t. wheel rim and tire. The wheel is supported like a rocker arm by means of a spring strut and an axle. This axle or wheel lever shaft at the same time is the drive shaft for the wheel itself. For this purpose, it has a drive gearwheel with external teeth, which is in engagement with an internal toothing connected to the outer wheel rim. The drive shaft is driven at an outer end by a motor gear unit, for example via a chain, belt or spur gear drive. For its second function as a swing arm, the drive shaft is mounted at its outer ends via plain or roller bearings into the frame of the two-wheeler. The inner component of Traction‑X, which is non-rotational w.r.t. the wheel rim, is mounted statically determined onto the combined drive and wheel lever shaft by means of a ball bearing and a needle bearing. The helical gear unit and the bearings inside the housing made of the inner wheel ring and wheel rim can be sealed to the outside by means of radial shaft seals. Thus, the entire Traction‑X drive arm wheel suspension can be fully oil-lubricated.

In a second variant of the invention the wheel is supported by means of three rollers, which engage and roll in a ring groove. This replaces the very large ball bearing. Again, this arrangement results in an inner component that is not rotating w.r.t. wheel rim and tire. The roller casings protruding into the inside of the wheel slightly reduce the interior clearance, but yield some countering advantages. They can be used in a sealed variant that is lubricated for life. Within a scooter of moderate drive power, oil bath lubrication can be dispensed with, so that the two large radial shaft seals can be omitted. This in turn reduces the frictional moment in the system.

The use case of Traction‑X within a scooter was the motivation of the inventor. Therefore, the advantages of the invention for this application will be worked out in the section Innovation.

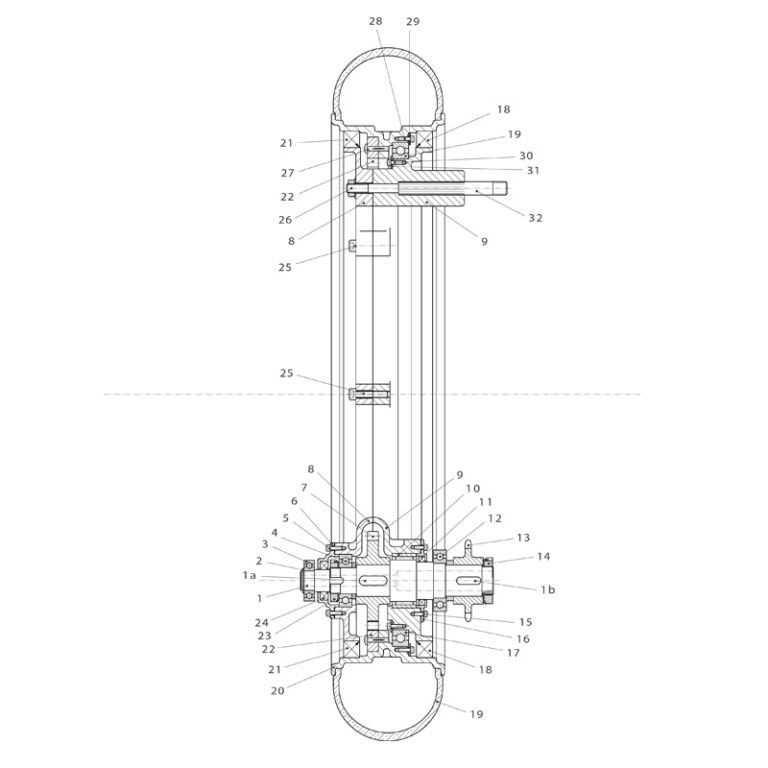

Drive-Train Swing-Wheel

1 combined drive and swing-wheel shaft

1a parallel key

1b keyway

2 retaining ring and ring groove

3 grooved ball bearing (movable)

4 deep groove ball bearing (fixed)

5 cylinder screw

6 left housing cover

7 gear wheel with external teeth

8 housing cover and right-hand side wheel hub

9 right-hand side wheel hub

10 needle bearing (movable)

11 radial shaft sealing ring

12 deep groove ball bearing (fixed)

13 drive sprocket for chain drive

14 shaft nut with lock washer and shaft groove

15 cylinder screw

16 right housing cover

17 grooved ball bearing

18 radial sealing ring wheel circumference right

19 tire

20 wheel rim

21 radial sealing ring wheel circumference left

22 drive gear with internal toothing

23 shaft nut with lock washer and shaft groove

24 radial sealing ring

25 bolted interface of the hub halves

26 screwed connection with suspension strut axle

27 riveted connection of wheel rim to drive gear 22

28 securing screw for wheel bearing outer ring

29 securing washer for wheel bearing outer ring

30 securing screw for wheel bearing inner ring

31 securing washer for wheel bearing inner ring

32 spring strut axis

33 spring strut with damper cartridge

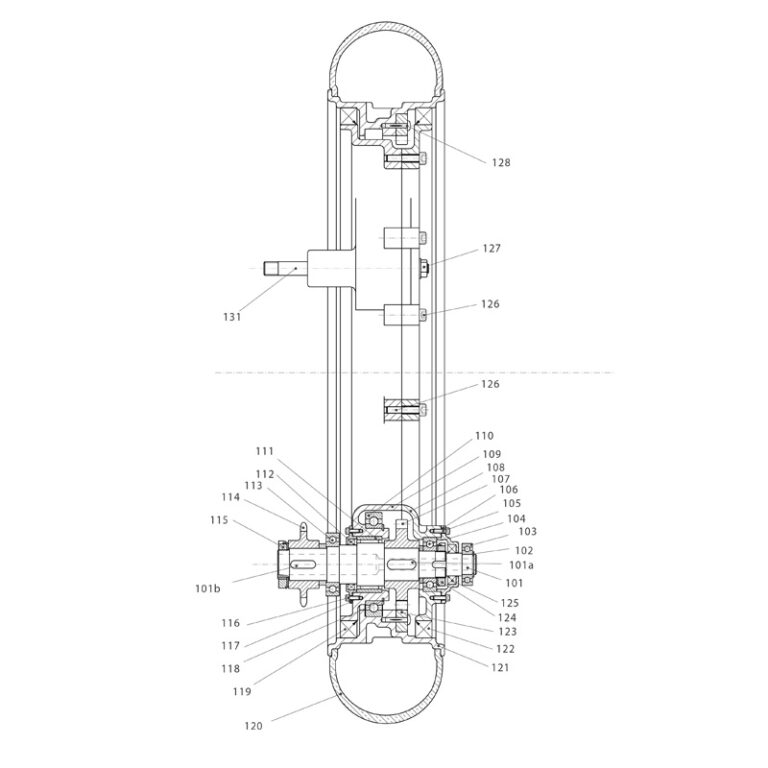

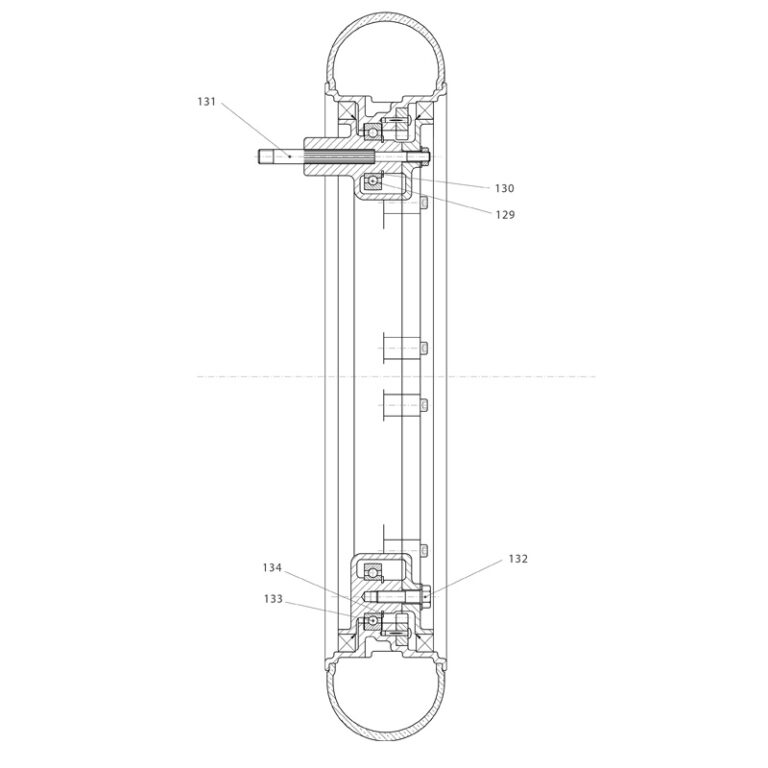

Drive-Train Roller-Ring Swing-Wheel

101 combined propulsion and swing-wheel shaft

101a ring groove

101b ring groove

102 retaining ring and ring groove

103 deep groove ball bearing (floating) for chassis

104 deep groove ball bearing

105 cylinder screw

106 left housing cover

107 drive gear with external teeth

108 housing cover or right-hand side wheel hub

109 housing cover or left-hand side wheel hub

110 track roller 1

111 needle bearing (movable)

112 radial shaft sealing ring

113 deep groove ball bearing (fixed)

114 chain drive sprocket

115 shaft nut with lock washer and shaft groove

116 cylinder screw

117 right-hand side housing cover

118 securing ring for track roller 1

119 radial shaft sealing ring wheel circumference left

120 tire

121 wheel rim

122 radial shaft sealing ring wheel circumference right

123 drive gear with internal toothing

124 shaft nut with lock washer and shaft groove

125 radial shaft sealing ring

126 screwed connection of two wheel rim halves

127 screwed connection with spring strut axle and track roller 2 housing

128 riveted connection of wheel rim to drive gear 123

129 track roller 2

130 securing ring for track roller 2

131 suspension strut axle

132 screwed connection for track roller 3 housing

133 track roller 3

134 securing ring for track roller 3

135 suspension strut with damper cartridge

THE INNOVATION

A compact secondary drive unit for a scooter

Traction‑X is a new and patented vehicle drive concept that enables small unsprung masses, extremely efficient use of space and large wheel diameters, which is particularly advantageous for scooters.

Traction‑X is a new power train concept for scooters that offers great advantages and that can optionally be used for other types of wheeled vehicles. The basis is the patent DE 10 2011 117 388 A “Device for the combination of secondary drive, rocker arm and drive wheel of a wheeled vehicle”.

When used for motor scooters, the Traction‑X invention has the following compelling advantages over drive systems with drive unit rockers:

- much smaller unsprung mass,

- significantly larger wheel diameter and

- shorter wheelbase.

Traction‑X thus combines all the advantages of the scooter with all the advantages of the motorcycle.

- A scooter equipped with Traction‑X has a small turning circle and a comparatively low mass moment of inertia around its vertical axis, because of which the scooter has outstanding agility and very good maneuverability. At the same time, the large possible wheel diameters give the scooter outstanding driving stability compared to conventional scooters and significantly improved ride comfort that is on a par with a motorcycle.

- Compared to scooters with a conventional swing arm drive train, the rear wheel suspension of a motor scooter equipped with Traction‑X has significantly lower unsprung masses, which enable sensitive responsiveness of the suspension and damping. The required tire air pressure can also be reduced with Traction‑X, so that the sensitivity of the suspension of this component is also considerably better.

- In both embodiments of Traction‑X, a free space remains within the torus-shaped swing arm, which can favorably be used to accommodate the electric motor, the drive motor gearbox or parts thereof, so that an extremely compact two-wheel drive entity is created. Thus, the footwell of the scooter is fully available again, which significantly increases the driver’s comfort.

- The driving stability is significantly better than with conventional scooters due to the higher gyroscopic moments of the larger wheels, i.e. just as great as with a motorbike.

- The driving safety is higher due to the larger contact area of the wheel with the road, i.e. the larger “tyre swath”, because thus the adhesion between tyre and road is also greater.

The favorable features of Traction‑X have been described and disclosed in the patent document, in the drawings and in the claims, so that they may easily be applied individually or in any combination. The aim is the beneficial implementation of the invention in various embodiments.

The invention Traction‑X can therefore also be used to design a bicycle of the future. For instance, there is the possibility of combining the rocker arm axis of the rear suspension with the pedal crank axis into a common and integral component. A multi-purpose axis like this would save weight and increase the stability of the wheel suspension. This partial aspect of the invention is already protected as an individual claim of the patent. The unique selling points for any future bicycle could therefore be

- light weight due to pedal crank bearing = swing arm bearing

- increased drive comfort due to a constant distance between rear wheel axle and pedal crank axle during the compression of the rear suspension